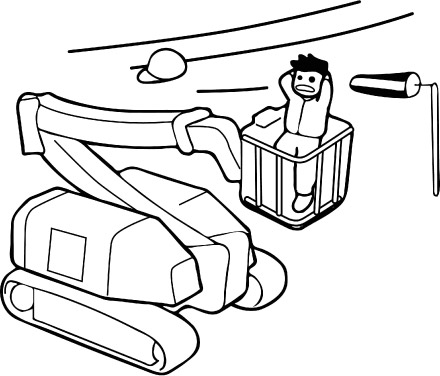

Our First Electric Access:

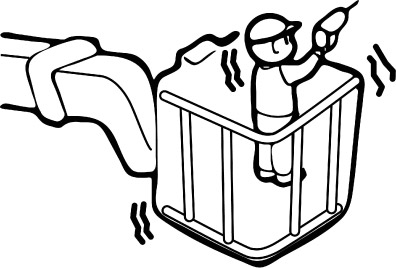

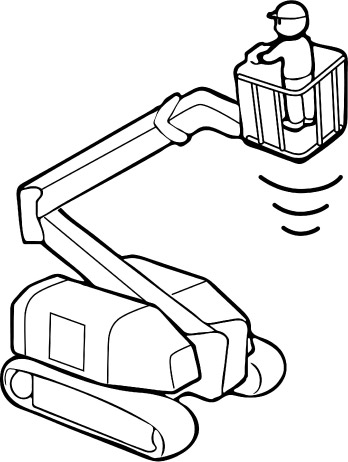

Crawler-type articulated boom lift

-

Work 8 hours during daytime => Full recharge overnight

(Nagano standard operation pattern). - Equivalent operation and traveling to engine-powered machines.

- Reduced noise, low vibration, low heat emissions ⇒ Ideal for work in urban areas, underground, tunneling and indoor.